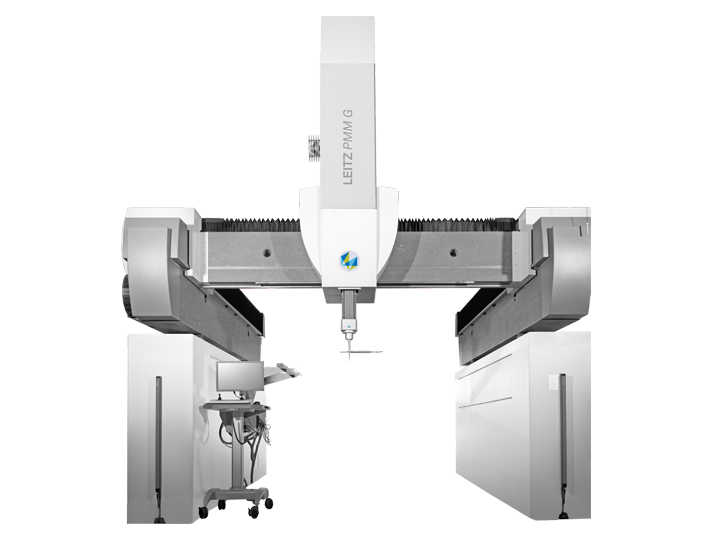

Gantry line

The Gantry Line is a line of gantry coordinate measuring machines (CMMs) that excel in the high-accuracy inspection of large machined parts due to their superior mechanical structure. Gantry Line is available in two versions: Classic and Performance. The optional SF-Kit (Shop Floor) is available for the installation of both Classic and Performance models for use in a workshop environment.