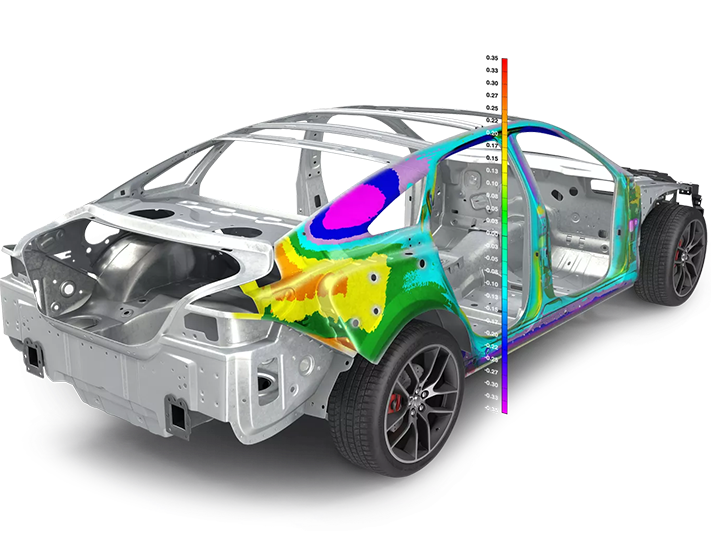

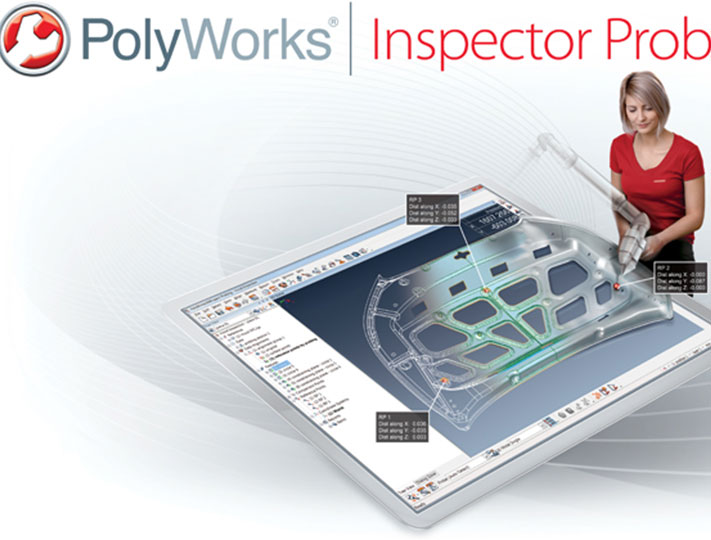

A universal 3D dimensional analysis and quality control software solution to control tool or part dimensions, diagnose and prevent manufacturing and assembly issues, guide assembly building through real-time measurements, and oversee the quality of assembled products by using portable metrology devices and CNC CMMs.

At the heart of PolyWorks|Inspector lies a powerful inspection engine with parametric data handling, mathematical algorithms certified by PTB, and extensive visual and audio feedback capabilities. It allows users to extract meaningful information from their measured 3D data, automate the inspection process when more than one piece is measured, and structure the presentation of measurement results to facilitate enterprisewide digital collaboration.

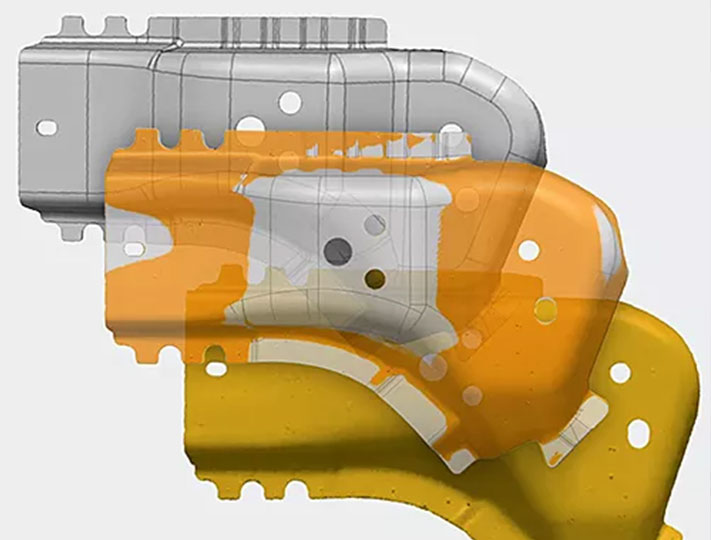

Best-fit measured surfaces and cross-sections to their nominal definition, with the option of constraining in rotation, translation, or within a tolerance zone.

Construct your alignment from features, datum targets, surface points, or edge points, and use weights and axial constraints to optimize the results.

Align your 3D measurement device while compensating for temperature changes, and use bundle adjustment to maximize the global accuracy.

Extract measured dimensions from point clouds, polygonal models, or probed points, and nominal dimensions from a CAD model or a measured part.

Benefit from a smart GD&T engine based on the latest ASME and ISO standards, with advanced DRF, material condition, datum modifier, and tolerance zone capabilities.

Extract advanced features on fan, compressor, and turbine blades to control and analyze dimensions, such as edge radius, thickness, length, width, angle, and area.

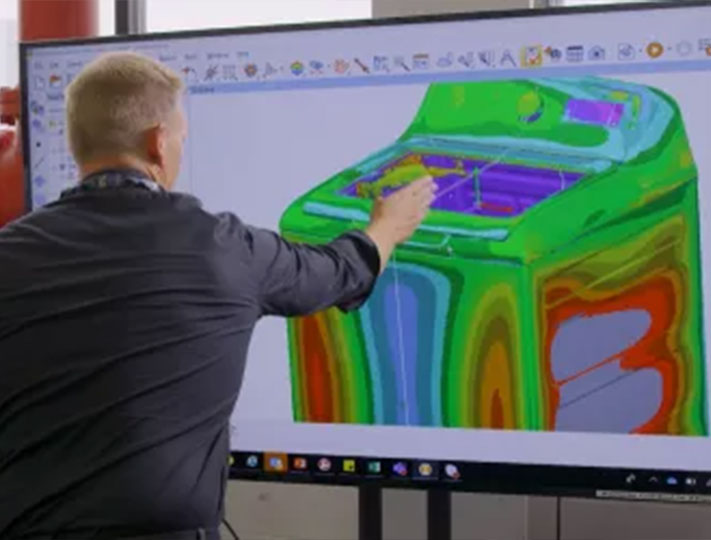

Feature-based dimensioningObtain surface, boundary, cross-sectional, or thickness measured-to-nominal deviations, and analyze them through a color map display

Evaluate advanced dimensions on fillets, design feature lines, and sheet metal part assemblies, such as radius, angle, bending, sharpness, flush, and gap.

Measure a feature’s diameter, position, or orientation, or distances and angles between two features, in 2D or in 3D, and configure the dimensions’ display intuitively.

Measure multiple pieces using different 3D measurement devices, and store them in a single project folder using an optimal format that minimizes disk space usage.

Play Inspection toolUse the powerful Play Inspection and Sequence Editor tools to automate measurement workflows by ordering and triggering operations.

Macro scriptingAdd macro scripts to your measurement workflows to apply proprietary techniques, provide special feedback, or interconnect to other systems

Organize projects containing hundreds of dimensional & GD&T controls into small & logical groups of controls, with individual controls tied to specific alignments.

Access a global list of controls sorted by characteristic index, and display critical results in 3D with the preferred point of view for easier dimensional analysis and reporting.

Assess the repeatability and predictability of your manufacturing processes with multipiece statistics automatically calculated for object dimensions and surface deviations.

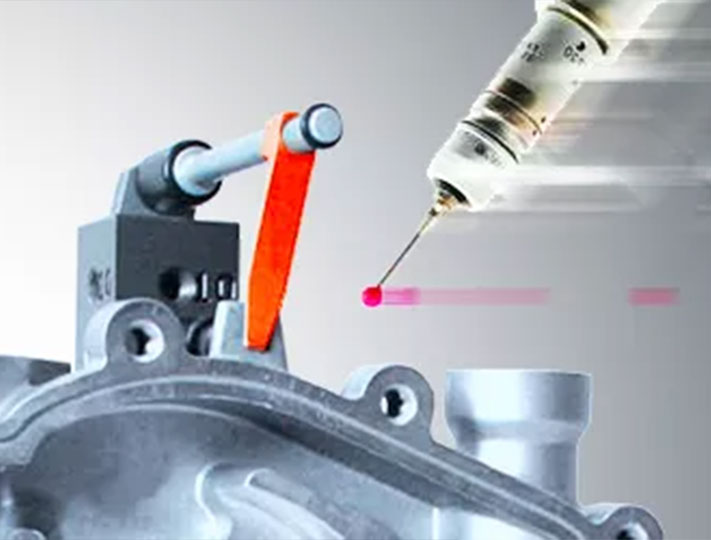

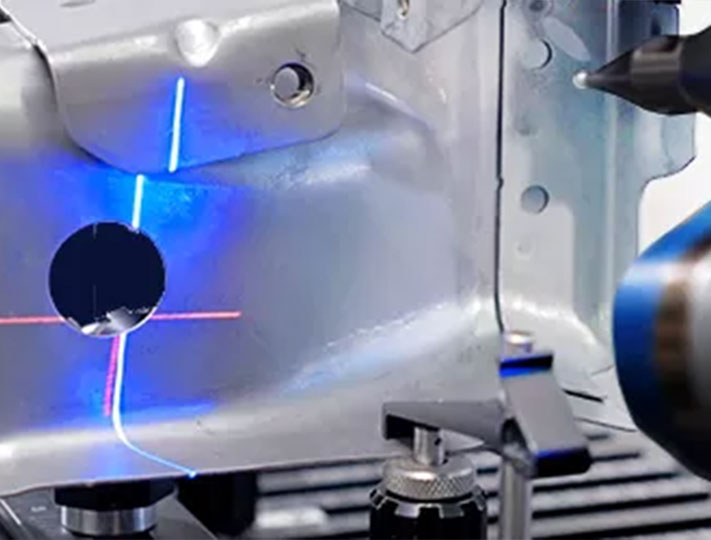

Renowned for the power and stability of its direct hardware interfaces, PolyWorks|Inspector offers an extensive set of guidance technologies that the world’s largest manufacturing OEMs trust to implement efficient, precise, and repeatable measurement processes for portable metrology devices.

Tens of thousands of portable arm operators worldwide enjoy the reliability and efficiency of our scanning and probing workflows every day

We provide innovative laser-tracker-based scanning technologies that accelerate the analysis & dimensional control of your large parts.

Minimize rework time when assembling large aerospace structures by scanning them using a spherical grid digitizer and simulating.

Integrate additional measurement devices or in-house proprietary measurement techniques by creating and embedding macro scripts.

Produce great scanning results under all circumstances thanks to our unique real-time quality meshing technology that computes and displays quality metrics in real time.

Get real-time feedback on scanned surface, curve, and circumference coverage with guidance graphics that indicate where an operator should capture additional scans.

Use images, text, 3D graphics, & tolerances to deploy guided probing inspection projects that improve operator efficiency & ensure measurement repeatability.

Accurately track part location during assembly using digital readouts, simultaneously displaying real-time measured reflector positions from multiple laser trackers.

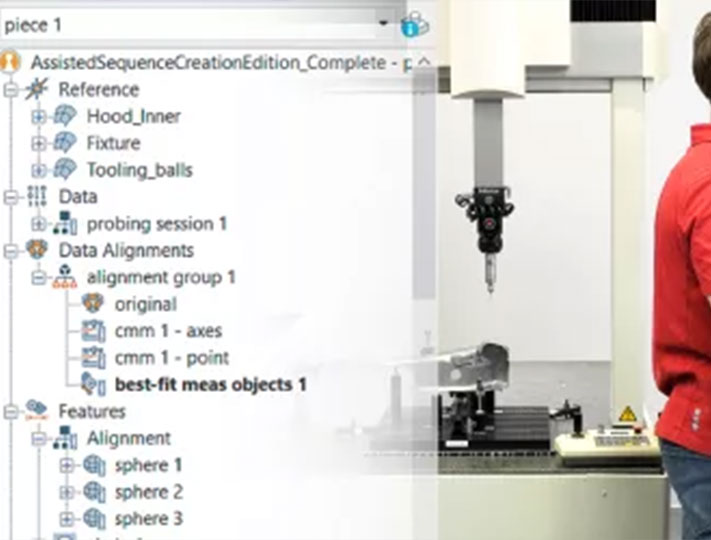

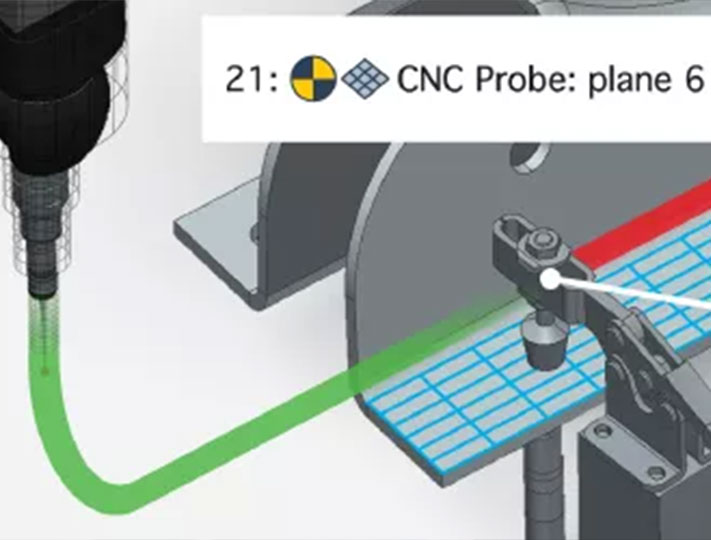

PolyWorks|Inspector has reinvented the way inspection projects are set up and executed on CNC CMMs, within a flexible, user-friendly, and efficient CNC CMM operational paradigm, similar to the one we offer for portable metrology devices.

We deliver shorter and easy-to-understand CNC CMM sequences, as our nominal features, dimensions, and reports are created and managed outside of the sequence editor.

Select objects to be measured and let the sequence editor automatically find the proper tool orientations, the optimal measurement order, and collision-free measurement paths.

Our intelligent sequence

editor provides immediate feedback when illogical or incorrect operations are detected, and lets you repair detected mistakes in a single click.

We offer powerful collision analysis and avoidance technologies that detect potential tool collisions in

real time and automatically modify the toolpaths to prevent them.

Build your measurement sequence once for a specific CNC CMM configuration, then use our conversion tool to automatically adapt it to any CNC CMM brand or type.

Avoid costly damages by detecting, in real time, potential tool collisions with parts or fixtures prior to launching a CNC measurement operation online.

To perform additional measurements, just create and select new measurement objects and let the sequence editor optimally insert them within your CNC CMM sequence.

Use a portable laser scanner to measure the fixtures for collision analysis purposes, or a scanning arm to measure surfaces and features that can’t be reached by the CMM

| PREMIUM | STANDARD | PROBING++ | PROBING | GAUGING | |

|---|---|---|---|---|---|

| Single-point measuring device for portable metrology and manual CMMs | • | • | • | • | |

| Single-point measuring device for CNC CMMs | • | • | |||

| Point cloud digitizer for portable metrology | • | • | |||

| Point cloud digitizer for CNC CMMs | • | ||||

| Measurement collection for digital gauges | • | • | • | • | • |

| Manual measurement data entry and visual checks | • | • | • | • | • |

| Real-time quality meshing and offline point cloud meshing | • | • | |||

| PolyWorks|Modeler™ Light module | • | ||||

| PolyWorks|AR™ plug-in | • | ||||

| IGES/STEP neutral CAD file translator | • | • | • | • | • |

| Part alignment toolset | • | • | • | • | • |

| Dimensional control toolset | • | • | • | • | • |

| Smart GD&T toolset | • | • | • | • | • |

| Reporting toolset | • | • | • | • | • |

| Simulation mode for offline project setup | • | • | • | • | • |

| Repeatable multipiece measurement workflows | • | • | • | • | • |

| Statistical Process Control toolset (SPC) | • | • | • | • | • |

| Native CAD file translators | Option | Option | Option | Option | |

| Airfoil gauges | Option | Option | Option | Option | |

| One-year support/maintenance | • | • | • | • | • |

| Two complimentary seats to attend a Basic classroom training | • | • | • | • |

| Computer Requirements | Minimum Computer Requirements* | Recommended Computer Requirements** |

|---|---|---|

| CPU | Dual-core CPU | Quad-core CPU |

| RAM | 4 GB | 32 GB |

| Graphics cards | Hardware-accelerated, professional OpenGL graphics card (NVIDIA-certified cards and drivers) equipped with 1 GB of memory | NVIDIA Quadro series graphics card equipped with 2 GB of memory (NVIDIA-certified card and Drivers) |

| Operating system | 64-bit Windows 10, 8.1, or 7 Professional Edition | 64-bit Windows 10, 8.1, or 7 Professional Edition |

| Input device | Two-button mouse with wheel | Two-button mouse with wheel |

Please fill out the form to request a quote. We will get back to you within 24 hours of receiving your request. Thank you for your patience

All Rights Reserved | 2B DIGITAL © 2025

جميع الحقوق محفوظة | 2B Digital © 2025

صمم بواسطة Thinkadv